|

| Completed and sliding effortlessly! |

Ok, this homeowner wanted new sliding hinges on the old drawers she had in her kitchen which were just wood sliding on wood drawers. After 100 years they finally gave up and the inner rails on the drawers broke, came unfastened and wore out. She has not used her drawers in a very long time because she could not open them. She is also getting older and just could not pull the weight of the lower drawers any more so she never got into the lower drawers because they were to heavy and hard to pull out. Now the old drawers were not anything to special, just wood and nails shaped into a box with nailed joints and bottoms, I offered to build new drawers but keep the old faces and that is exactly what I did! Check it out.

|

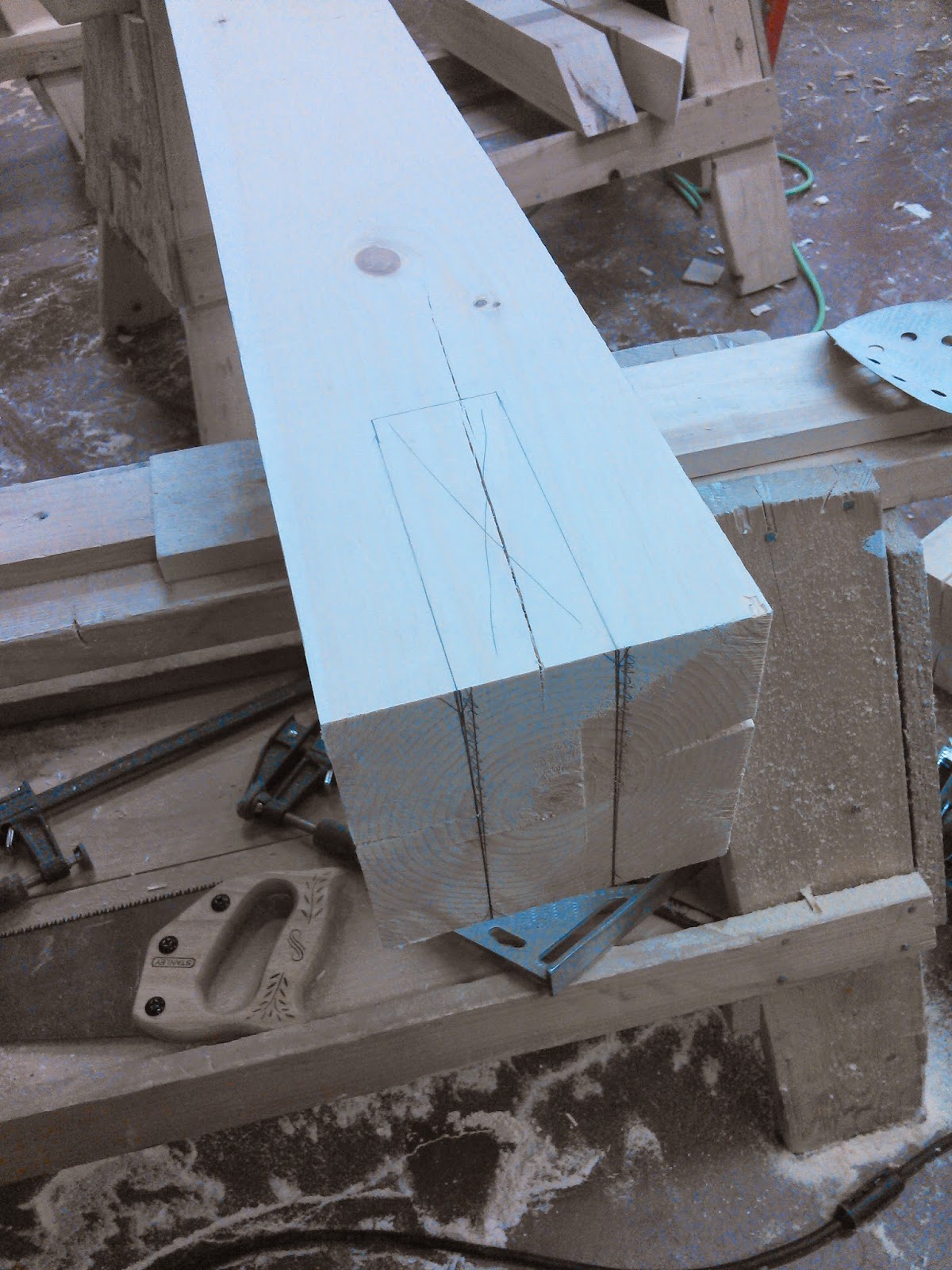

| This is my shop.. a door on saw horses. |

|

| This was my first attempt at dovetail joints |

|

| The first box unstained |

This is going to be the oak shelf inside the drawers.

|

| Oak 1/4" Plywood with brush on Lacquer |

|

| New Curly Maple Boxes vs. Old Quarter-sawn Hard Yellow Pine |

|

| Work bench = a bi-folding door and two saw horses |

|

| Dovetail Jig |

|

| Glue ups |

|

| Vent Chamber |

|

| the first drawer to be installed |

I made the drawers less wide then the opening so they would work inside the opening with sliders and I made them shorter so that I could expose my dovetails when I was putting the sliders on. Planning for these when deciding the sizes of drawers makes the install a breeze!

I made the drawers less wide then the opening so they would work inside the opening with sliders and I made them shorter so that I could expose my dovetails when I was putting the sliders on. Planning for these when deciding the sizes of drawers makes the install a breeze!  |

| Completed and sliding effortlessly! |

|

| Same look... 100% better function! |